Features:

Features:

The solution, emulsion, suspension, paste material, spray drying into dry powder, fast, high efficiency, less process. Heat-sensitive materials, can maintain the material color, flavor, fragrance, dry powder, good solubility, high purity. The aircraft environment health is good, the basic implementation of automation can be widely used in chemical, petrochemical, light industry, food, medicine, construction, ceramics, forestry and other chemical industries.

Applications:

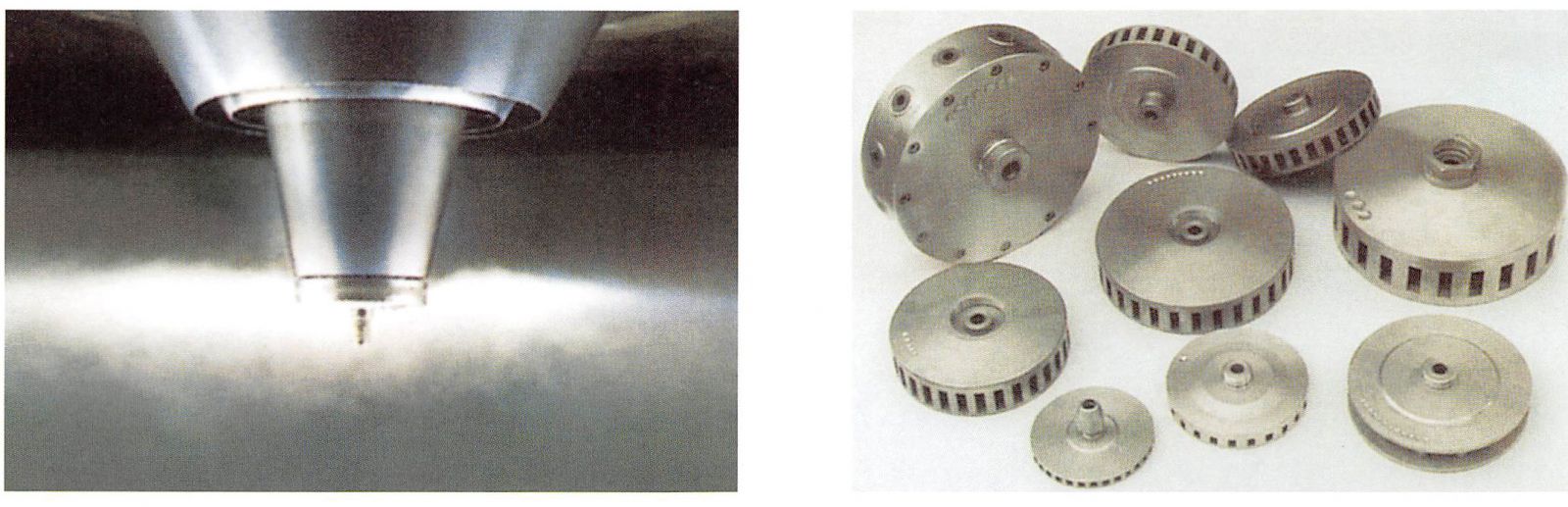

The Centrifugal granulation of the special materials for the ceramic industry, the chemical industry, the dyes and other special materials can be adjusted to the best distribution curve (100 mesh -350 mesh), the main technical performance, the index Can reach the world advanced level.

| Project / model |

ZPG Centrifugal granulation spray Drying machine |

||||||||||

| 15 | 25 | 50 | 100 | 150 | 200 | 300 | 500 | 800 | 1000 | 3500 | |

| Maximum water evaporation (kg / h) |

15 | 25 | 50 | 100 | 150 | 200 | 300 | 500 | 800 | 1000 | 3500 |

| Spray form |

Centrifugal granulation atomizer |

||||||||||

| Atomizer speed (r / min) |

Frequency |

||||||||||

| Heat source (optional) |

Fuel, gas, coal, steam, electricity and so on |

||||||||||

Note: The amount of water evaporation and material properties, including heat and hot air import and export temperature.