.jpg) Brief:

Brief:

● This unit is a device that can dry and granulate at the same time. According to the process requirements can adjust the liquid pump pressure, flow, the size of the nozzle, get the required proportion of spherical particles.

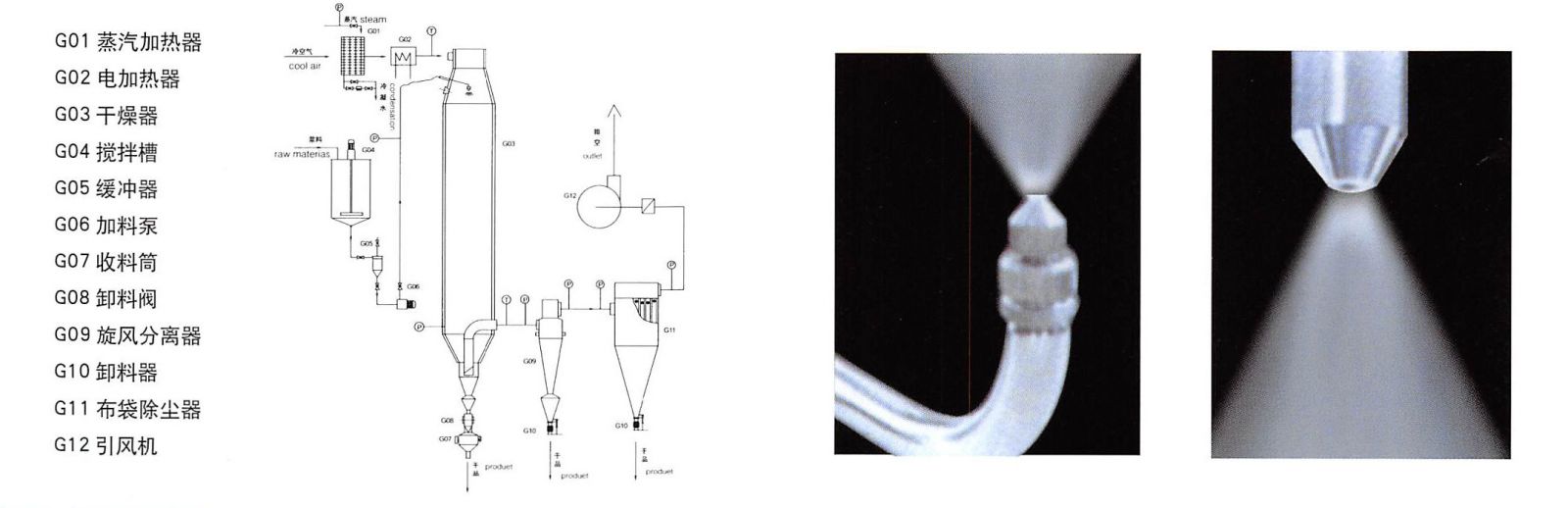

The working process of the unit: the material through the feed pump evenly input, sprayed from the compressed air mist into mist droplets, and then with the hot air co-current decline, most of the powder from the bottom of the collection, The fine powder is separated by a cyclone separator, and the exhaust gas is discharged by an exhaust fan. The powder is collected by a powder collecting cylinder located at the bottom of the cyclone separator. The outlet of the fan can also be equipped with a secondary device with a recovery rate of 96-98% or more.

● The heat source device of this unit adopts steam heating or electric heater, which has the advantages of convenient operation, quick start, compact structure, clean and clean air. Also in the electrical control cabinet equipped with electric heater control and adjustment device, so that the inlet temperature stepless adjustment. For the power shortage area can be used steam heating or coal, fuel hot air furnace, etc., local or all instead of electric heating device. The factory can be based on the actual needs of users to provide different heating methods.

Features:

● Drying speed, product size adjustable range.

● The product is spherical particles, uniform material, fluidity, good solubility, high purity, good quality;

● Use a wide range, can be hot air drying, granulation, can also be spray crystallization, spray reaction.

● can be equipped with fine powder to send back, and then wet agglomeration system to meet the user's material size requirements.

● Simple and stable operation, easy to control, easy to achieve automation operations, product size, bulk density, water can be adjusted within a certain range.

Applications:

The spray drying machine is not suitable for high - pressure atomization and centrifugal atomization. It is not suitable for high - pressure atomization and centrifugal atomization. dry.

Technological process:

Technical Parameters:

| Parameters / Type | QPG-5 | QPG-25 | QPG-50 | QPG-100 | QPG-150 | QPG-200 | |

| Evaporation |

△t=150~90(℃) | 1.5 | 7.5 | 15 | 30 | 45 | 60 |

| △t=200~100(℃) | 2.5 | 12.5 | 25 | 50 | 75 | 100 | |

| △t-=250~100(℃) | 3.75 | 18.75 | 37.5 | 75 | 112.5 | 150 | |

| △t=300~100(℃) | 5 | 25 | 50 | 100 | 150 | 200 | |

| △t=350~110(℃) | 6 | 30 | 60 | 120 | 200 | 240 | |

| Compressed air |

0.3 | 0.4 | 0.6 | 1.5 | 2.7 | 3.4 | |

| Compressed empty |

0.4 | 0.6 | 0.7 | ||||

| Heat source |

Electricity, electricity + steam, kerosene hot air stove | ||||||

| Heat supply |

1 | 5 | 10 | 20 | 30 | 40 | |

| Fan power |

0.75 | 2.2 | 4 | 7.5 | 11 | 15 | |

Note: The equipment is greater than 200 can be made according to the actual needs of equipment manufacturing; fan power for the standard process, such as bagging bag and recovery of solvent will increase.