Application

Application

※ It is suitable the raw materials that need to dry at low temperature (for example, biochemistry products in chemical, pharmaceutical and foodstuff industries.) particularly it is suitable for the raw materials that are easy to oxidize, volatilize and have strong heat sensitive and toxic and not permitted to destroy it crystal in drying.

Principle

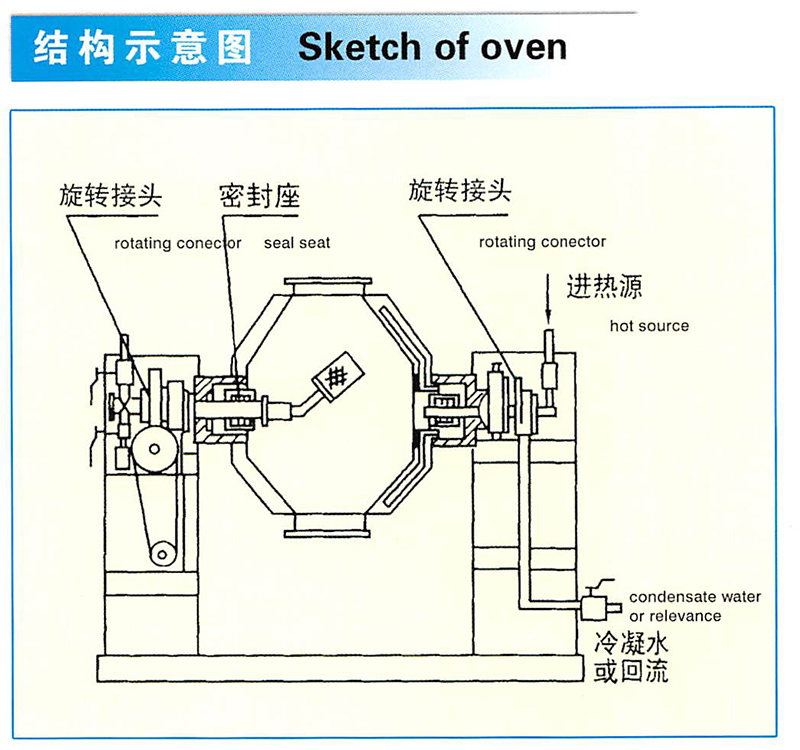

※ Let heat source (for example, low pressure steam, ir heat conduct oil) pass through the sealed jacket. The heat will be ransmitted to raw material to be ired through inner shell.

※ Under driving of power, the tank is rotated slowly and the raw material inside it as mixed continuously. The purpose of reinforced drying can be realized.

※ The raw material exists at the state of vacuum. The drop of steam pressure makes the moisture(solvent)at the surface of raw material become saturation and will

※ The raw material exists at the state of vacuum. The drop of steam pressure makes the moisture(solvent)at the surface of raw material become saturation and will

evaporate. The solvent will be discharged through vacuum prmp and recovered in time. The inner moisture(solvent )of raw material will infiltrte, evaporate and discharge continuously. The three processes are carried out unceasingly and the purpose of drying can be realized within a short time.

Feature

※ When oil is used to heat, use automatic constant temperature control. It can be used for drying biology products and mine. Its temperature of operation can be adjusted from 20-160℃ and within ±2℃.

※ Compared with ordinal drier, its heat efficiency will be over 2 times.

※ The heat is indirect. So the raw material can not be polluted. It is conformity with the requirement of GMP. It is easy in washing and maintenance.

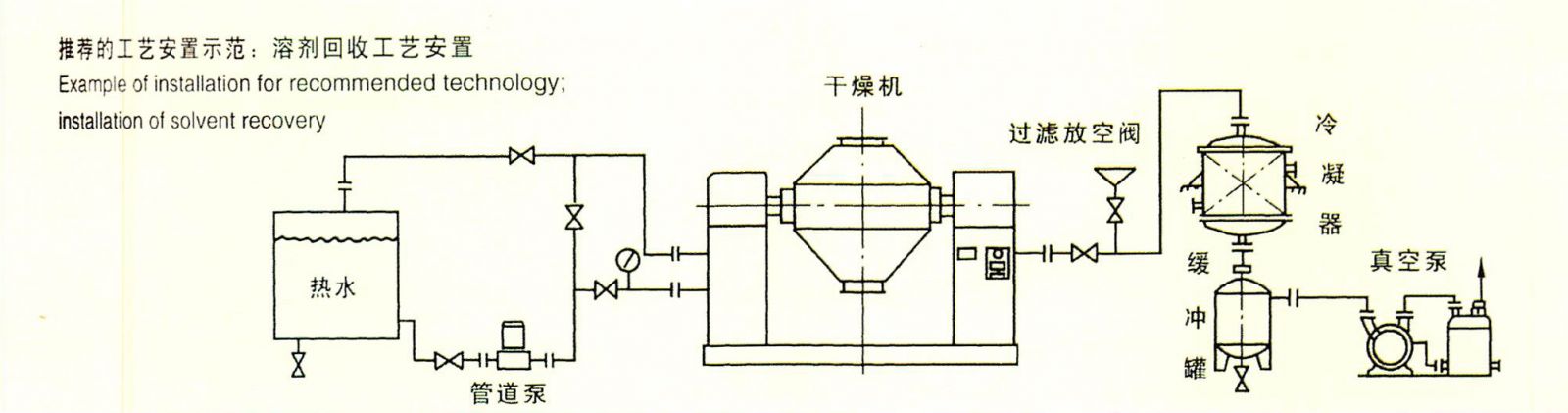

Flow chart

技術(shù)參數(shù)

| item | type | ||||||||||

| name | unit | 100 | 200 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3000 | 4500 |

| total volume | L | 100 | 200 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3000 | 4500 |

| working volume | L | ≤50 | ≤100 | ≤175 | ≤250 | ≤375 | ≤500 | 4750 | <1000 | ≤1500 | ≤2250 |

| heating area | m2 | 1.16 | 1.5 | 2 | 2.63 | 3.5 | 4.61 | 5.58 | 7.5 | 9.6 | 13.8 |

| revolution | rpm | 3-13 | |||||||||

| power | kw | 0.75 | 1.1 | 1.5 | 1.5 | 2 | 3 | 3 | 4 | 5.5 | 7.5 |

| height of rotating frame | mm | 1810 | 1910 | 2090 | 2195 | 2500 | 2665 | 2915 | 3055 | 3330 | 4210 |

| total weight | kg | 550 | 700 | 900 | 1100 | 1200 | 1300 | 1500 | 2000 | 3000 | 4000 |

| design pressure inside the tank | Mpa | -0.1-0.15 | |||||||||

| design pressure of jacket | Mpa | ≤0.3 | |||||||||

Attentions to order

※ Its heating has three ways i.e. steam, hot water, hot conduction oil.

※ When order please indicate the temperature of raw material to be undertaken or the operation temperature of drier in order to choose or provide suitable heat source for you.

※ When dry viscous raw material, our factory will design special sirring device in the chamber.

※ The cost of complete equipment should be increased in accordance with the needs.